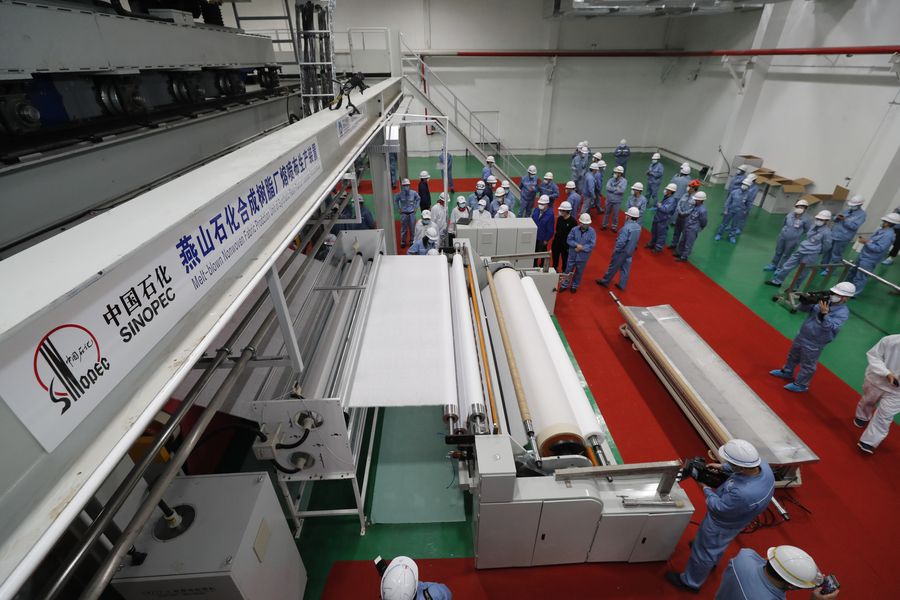

Photo taken on April 15, 2020, shows the production line of Sinopec Beijing Yanshan Petrochemical Co., Ltd. in Beijing, capital of China. (Provided to Xinhua)

The newly-started lines of Sinopec bring the daily fabric production capacity to 12 tonnes, an amount sufficient to produce 12 million medical masks.

BEIJING, April 16 (Xinhua) -- China's largest oil refiner Sinopec has built and operated another two production lines of melt-blown non-woven fabric in Beijing, which further boosted the raw material supply to mask producers.

The operation of the new lines started on Wednesday, bringing the daily fabric production capacity to 12 tonnes, an amount sufficient to produce 12 million medical masks, according to Sinopec Beijing Yanshan Petrochemical Co., Ltd.

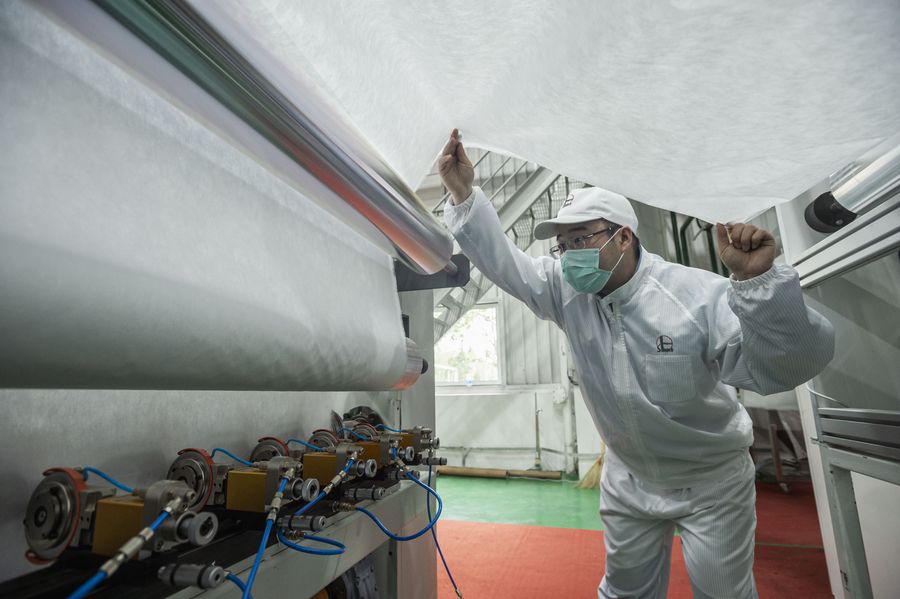

A worker checks the quality of the newly produced melt-blown non-woven fabric on April 15, 2020, in Sinopec Beijing Yanshan Petrochemical Co., Ltd. in Beijing, capital of China. (Provided to Xinhua)

As the essential material to make medical masks, melt-blown non-woven fabric is the filtering layer in the middle part of the mask.

The Sinopec Beijing subsidiary started building its first two production lines on Feb. 24, which was put into operation on March 8.

As of 8 a.m. Thursday, the company had produced 245.39 tonnes of melt-blown non-woven fabric, including 17.97 tonnes of fabric for the production of respirators.

Sinopec is the upstream producer of the polypropylene raw materials in the industrial mask chain. Faced with the market shortage of masks, the company invested 300 million yuan (42 million U.S. dollars) to build the production facilities in its subsidiary of Sinopec Beijing Yanshan Petrochemical Co., Ltd. in Beijing and Sinopec Yizheng Chemical Fibre in Jiangsu. ■